Table- I

| Number of cores and Nominal Area Of conductor |

Thickness Of insulation (Nom.) |

Thickness Of inner sheath (Minimum) |

Armour wire diameter or Steel strip (Dimension) |

Thickness of over sheath (Min) |

Approx. overall diameter |

Total weight approx |

Maximum DC resistance of conductor at 20 degree C |

Approx. AC resistence at operating temp.at 70 degree C |

| Sq.mm | mm | mm | mm | mm | mm | Kg/Km | Ohm/Km | Ohm/Km |

| 2X2.5 | 0.9 | 0.3 | 1.40 | 1.24 | 14.8 | 470 | 7.41 | 8.87 |

| 3×2.5 | 0.9 | 0.3 | 1.40 | 1.24 | 15.2 | 503 | 7.41 | 8.87 |

| 4×2.5 | 0.9 | 0.3 | 1.40 | 1.24 | 16.1 | 577 | 7.41 | 8.87 |

| 5×2.5 | 0.9 | 0.3 | 1.40 | 1.24 | 16.8 | 645 | 7.41 | 8.87 |

| 6×2.5 | 0.9 | 0.3 | 1.40 | 1.24 | 17.8 | 723 | 7.41 | 8.87 |

| 7×2.5 | 0.9 | 0.3 | 1.40 | 1.24 | 18.9 | 791 | 7.41 | 8.87 |

| 8×2.5 | 0.9 | 0.3 | 4×0.8 | 1.40 | 19.0 | 848 | 7.41 | 8.87 |

| 10×2.5 | 0.9 | 0.3 | 4×0.8 | 1.40 | 21.8 | 900 | 7.41 | 8.87 |

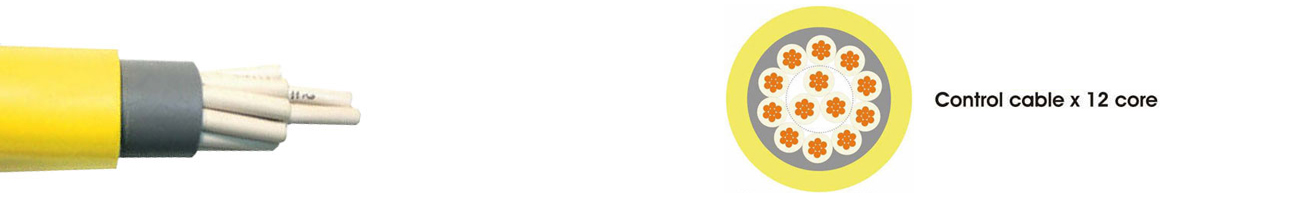

| 12×2.5 | 0.9 | 0.3 | 4×0.8 | 1.40 | 23.0 | 1034 | 7.41 | 8.87 |

| 14×2.5 | 0.9 | 0.3 | 4×0.8 | 1.40 | 23.7 | 1125 | 7.41 | 8.87 |

| 16X2.5 | 0.9 | 0.3 | 4×0.8 | 1.40 | 24.7 | 1231 | 7.41 | 8.87 |

| 19X2.5 | 0.9 | 0.3 | 4×0.8 | 1.40 | 26.4 | 1411 | 7.41 | 8.87 |

| 24X2.5 | 0.9 | 0.3 | 4×0.8 | 1.56 | 30.0 | 1682 | 7.41 | 8.87 |

| 27X2.5 | 0.9 | 0.3 | 4×0.8 | 1.56 | 30.8 | 1852 | 7.41 | 8.87 |

| 30X2.5 | 0.9 | 0.3 | 4×0.8 | 1.56 | 32.0 | 2012 | 7.41 | 8.87 |

| 37X2.5 | 0.9 | 0.4 | 4×0.8 | 1.56 | 34.0 | 2306 | 7.41 | 8.87 |

| 61X2.5 | 0.9 | 0.4 | 4×0.8 | 1.72 | 41.7 | 3450 | 7.41 | 8.87 |

Table-II

| Number of cores and Nominal Area Of conductor |

Thickness Of insulation (Nom.) |

Thickness Of inner sheath (Minimum) |

vArmour wire diameter or Steel strip (Dimension) |

Thickness of over sheath (Min) |

Approx. overall diameter |

Total weight approx |

Maximum DC resistance of conductor at 20 degree C |

Approx. AC resistence at operating temp.at 70 degree C |

| Sq.mm | mm | mm | mm | mm | mm | Kg/Km | Ohm/Km | Ohm/Km |

| 2X1.5 | 0.8 | 0.3 | 1.40 | 1.24 | 13.8 | 398 | 12.10 | 14.5 |

| 3X1.5 | 0.8 | 0.3 | 1.40 | 1.24 | 14.3 | 448 | 12.10 | 14.5 |

| 4X1.5 | 0.8 | 0.3 | 1.40 | 1.24 | 14.9 | 486 | 12.10 | 14.5 |

| 5X1.5 | 0.8 | 0.3 | 1.40 | 1.24 | 15.5 | 510 | 12.10 | 14.5 |

| 6X1.5 | 0.8 | 0.3 | 1.40 | 1.24 | 16.2 | 600 | 12.10 | 14.5 |

| 7X1.5 | 0.8 | 0.3 | 1.40 | 1.24 | 16.8 | 630 | 12.10 | 14.5 |

| 8X1.5 | 0.8 | 0.3 | 1.40 | 1.24 | 18.4 | 707 | 12.10 | 14.5 |

| 10X1.5 | 0.8 | 0.3 | 4×0.8 | 1.40 | 20.0 | 748 | 12.10 | 14.5 |

| 12X1.5 | 0.8 | 0.3 | 4×0.8 | 1.40 | 20.4 | 831 | 12.10 | 14.5 |

| 14X1.5 | 0.8 | 0.3 | 4×0.8 | 1.40 | 21.0 | 883 | 12.10 | 14.5 |

| 16X1.5 | 0.8 | 0.3 | 4×0.8 | 1.40 | 21.9 | 938 | 12.10 | 14.5 |

| 19X1.5 | 0.8 | 0.3 | 4×0.8 | 1.40 | 23.2 | 1041 | 12.10 | 14.5 |

| 24×1.5 | 0.8 | 0.3 | 4×0.8 | 1.40 | 26.4 | 1270 | 12.10 | 14.5 |

| 27×1.5 | 0.8 | 0.3 | 4×0.8 | 1.40 | 27.0 | 1384 | 12.10 | 14.5 |

| 30×1.5 | 0.8 | 0.3 | 4×0.8 | 1.40 | 28.0 | 1447 | 12.10 | 14.5 |

| 37×1.5 | 0.8 | 0.3 | 4×0.8 | 1.56 | 29.8 | 1718 | 12.10 | 14.5 |

| 61×1.5 | 0.8 | 0.3 | 4×0.8 | 1.56 | 36.2 | 2508 | 12.10 | 14.5 |

Construction (for above table I & II)

| Conductor | Annealed Bare copper / Tinned ( Solid /Stranded ) |

| Insulation | General purpose / HR PVC |

| Laid up | Cores laid up ( With suitable Fillers if necessary ) |

| Inner sheath | General purpose PVC / FRLS |

| Armouring | Round galvanised steel wire / Strip |

| Outer Sheath | General purpose PVC / FRLS |

* Dimensions specified in the table are with stranded conductors.